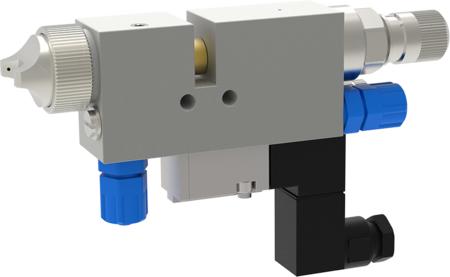

The MKD-IS spray valve is a electropneumatically controlled applicator for processing spray materials, e.g. release agents, adhesives or paints. It is suitable for both continuous and intermittent application.

A special of this valve is the integrated atomizing air valve, which allows an independent regulation of purging air time (for cleaning the nozzle and needle point).

The very short air channels within the valve and the direct mounted 5/2 way solenoid valve give this valve very fast and exact needle intermission cycles. Depending on nozzle dimension, fluids of different viscosities can be applied. Also different versions of air caps allow optimal spray jets for any application.

The function of the needle is: to open in response to compressed air and to close in response to spring pressure.

- Available nozzle sizes:

ø 0.2 / 0.3 / 0.5 / 0.8 / 1.0 / 1.2 / 1.5 / 2.0 / 2.5 mm - Raster regulation for easy setting of the material flow

- Solenoid valves in different tensions

(24 V/DC / 110 V/AC / 230 V/AC) - Different nozzles and air caps for individual application requirements

- Optional with proximity switch

Technical data:

| Measurements: | 115 x 80 x 22 mm (incl. solenoid valve) |

| Weight: | approx. 500 g |

| Control air pressure: | max. 6 bar |

| Atomising air pressure: | 0.5 - 5 bar |

| Material pressure: | max. 50 bar |

| Gun body: | stainless steel |

| Nozzle + needle: | stainless steel |

| Gaskets: | Viton® (other materials on request) |

Special designs on request. Technical alterations reserved. For further information please contact us.