- Products

- Material supply

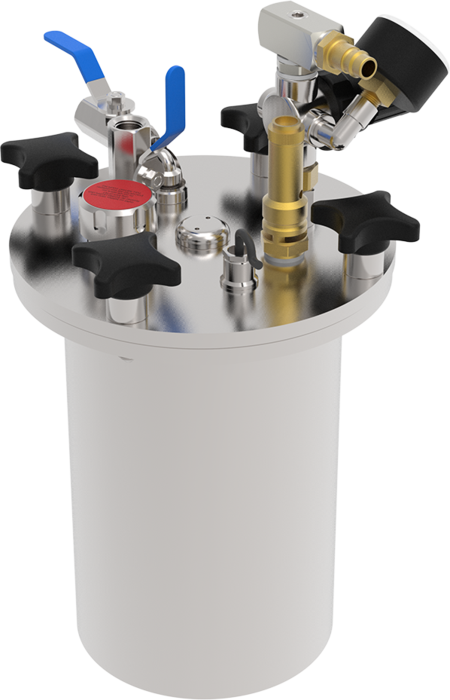

- Pressure tanks

- V2 / V5 / V10

When spraying material continuously in considerable volume, the employment of a material pressure tank pays off within a short period of time. In standard version the material pressure tanks V2, V5 and V10 are made from stainless steel.

Advantages compared with spraying by cup guns:

- less interruptions for refilling flow cups

- clean working area

- better handling of spraygun

- pressure feed results in more fluid output per unit of time

- constant flow of fluid improves quality of lay on

- reduced fluid mist by less air friction with fluid particles

- internal mix nozzles in sprayguns for special effect paints also for reduced mist effects

- several sprayguns can be fed simultaneously (optional)

Material pressure tanks V2, V5 and V10 are equipped with:

- lid locked by 5 cross grips

- air stirrer motor (optional)

- filler cap

- safety valve (type approved)

- pressure reducer for atomizing air

- pressure reducer for fluid

- nipple for quick coupler (air inlet)

- cock for fluid outlet

- cock for atomizing air outlet

Technical data:

| Modell |

Volume ltr. |

Operating Pressure (max) bar |

Test Pressure bar |

Inner Diameter mm |

Height (approx.) mm |

| V 2 | 2 | 6 | 7,8 | 125 | 300 |

| V 5 | 5 | 6 | 7,8 | 214 | 330 |

| V 10 | 10 | 6 | 7,8 | 214 | 460 |

Special designs on request. Technical alterations reserved. For further information please contact us.